Improve Your Manufacturing Operations with Odoo Manufacturing Management Software

REQUEST A QUOTE NOW!

Why Choose Odoo Manufacturing Management Module?

Our Odoo Manufacturing Management Module offers end-to-end manufacturing solutions, enabling businesses to:

• Automate production planning and scheduling

• Monitor real-time operations for improved efficiency

• Optimize material procurement and inventory control

• Streamline work center management and routing

• Enhance reporting and analytics for better decision-making

Key Features of Odoo Manufacturing Management Software

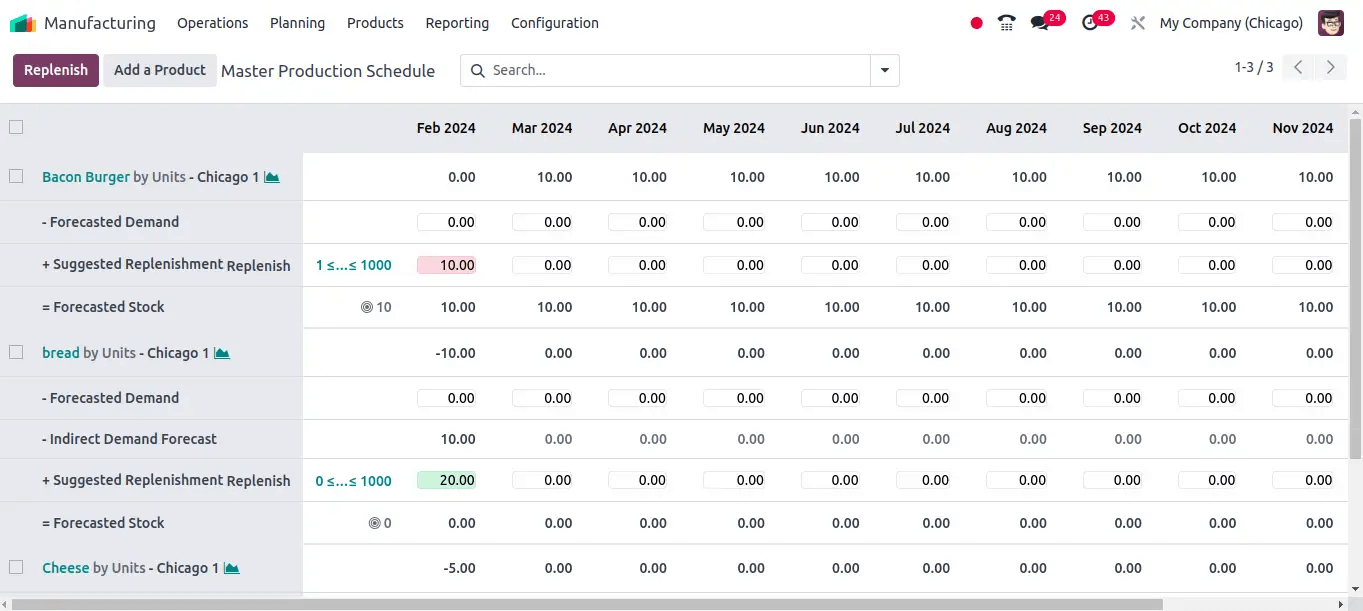

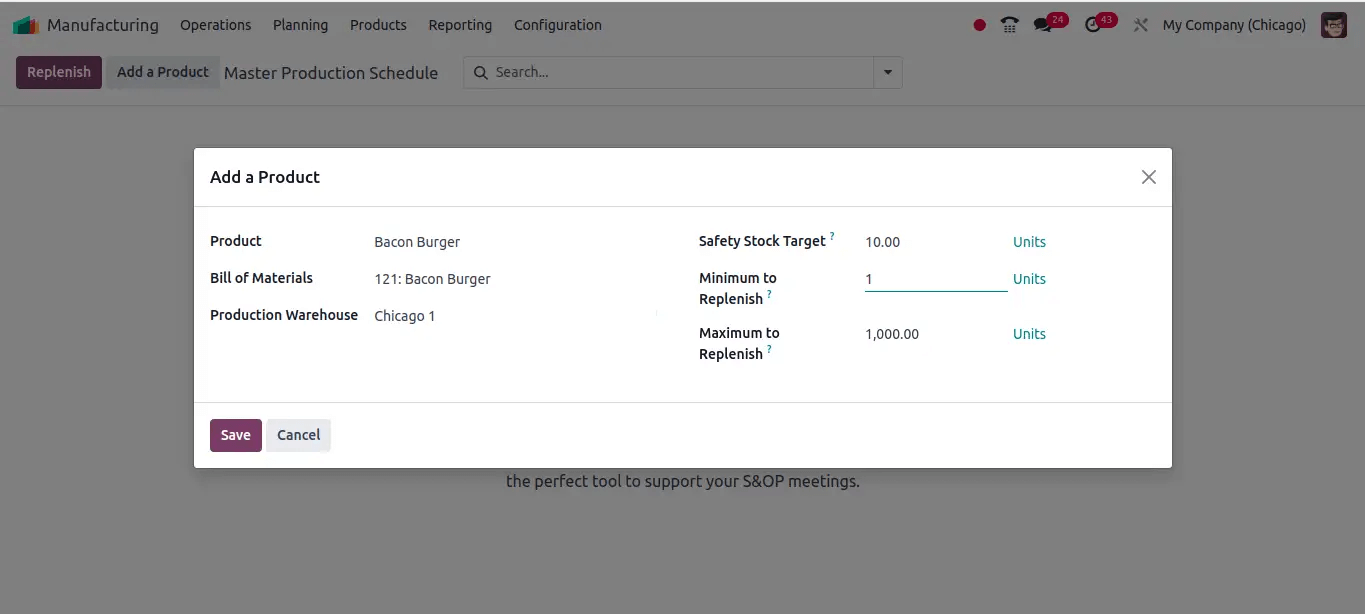

Master Production Schedule (MPS)

The Master Production Schedule (MPS) in Odoo Manufacturing Management Software allows businesses to efficiently manage Bill of Materials (BOM), work centers, operations, and routing. This feature helps manufacturers forecast demand and allocates resources efficiently, reducing delays and enhancing productivity.

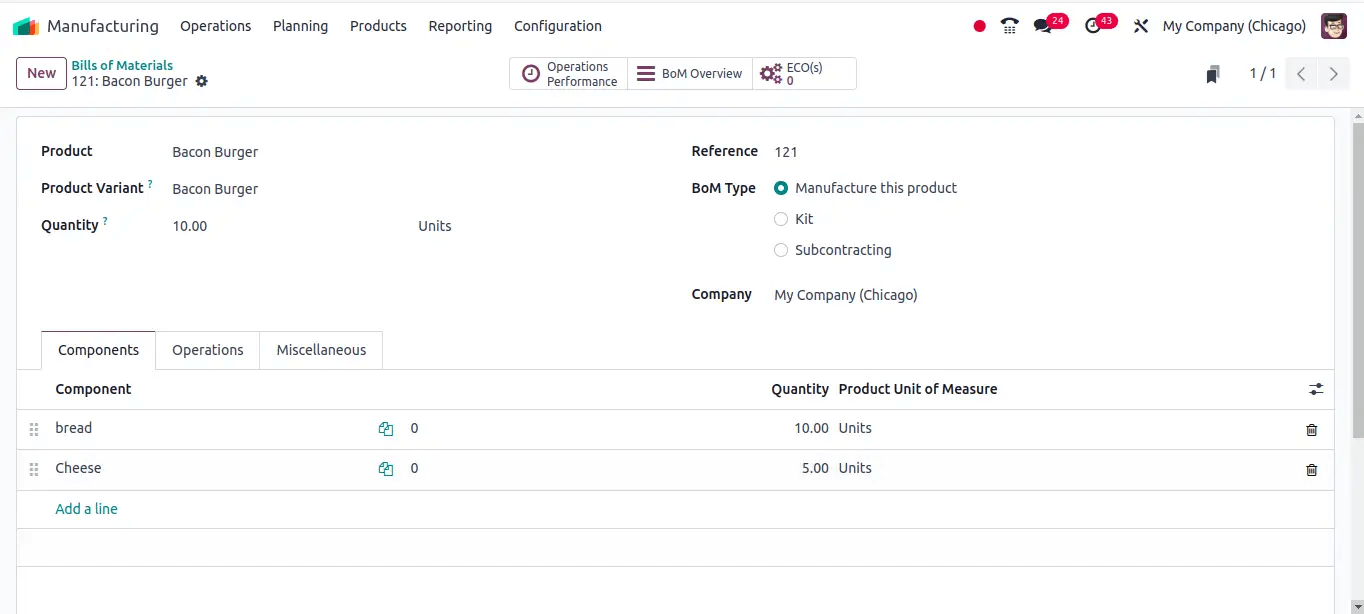

Bill of Materials (BOM)

Work Order Management

Manufacturing Routing

Work Center Management

Quality Control

Inventory & Material Procurement

Work-in-Progress (WIP) Tracking

Barcode & IoT Integration

Manufacturing Costing

Product Lifecycle Management (PLM)

Manage product lifecycles effectively with Odoo’s PLM feature. This ensures better collaboration, document control, and version management, making it easier to improve designs and reduce development time.

Maintenance & Repairs

With Odoo Manufacturing Management Software, manufacturers can schedule preventive maintenance, track machine repairs, and minimize unexpected breakdowns, ensuring uninterrupted production.

MPS -Make To Order

Features

- After selecting the Sales Order, Start date and Delivery date automatically populates

- Start Date can be changed so the delivery date changes accordingly

- Track each Sales Order through each respective routing step and know where each part should be at any particular time

- Keep track of all required resources for each manufacturing step and know the availability of each resource at any particular time

- Represent time in a detailed manner (e.g. minute by minute). Machine run time can be defined as - per hour

- Schedule orders (i.e. manufacturing steps) only when resources are available

- Detailed working Time for work centers

- Consideration of preventative maintenance (Resource Leave) and other machine down time in Scheduling

- Can be Scheduled against single Sales Order or Sales Orders for particular period

- Routing selection is provided at the time of Schedule generation

- Multiple Tentative Schedules can be generated and changed before freezing it

Benefits of Odoo Manufacturing Management Module

Enhanced efficiency through automation

Real-time tracking of production workflows

Optimized inventory & material management

Increased profitability by reducing waste and errors

Seamless integration with sales, purchases, and accounting modules

Bill of Materials (BoM):

Master production scheduler

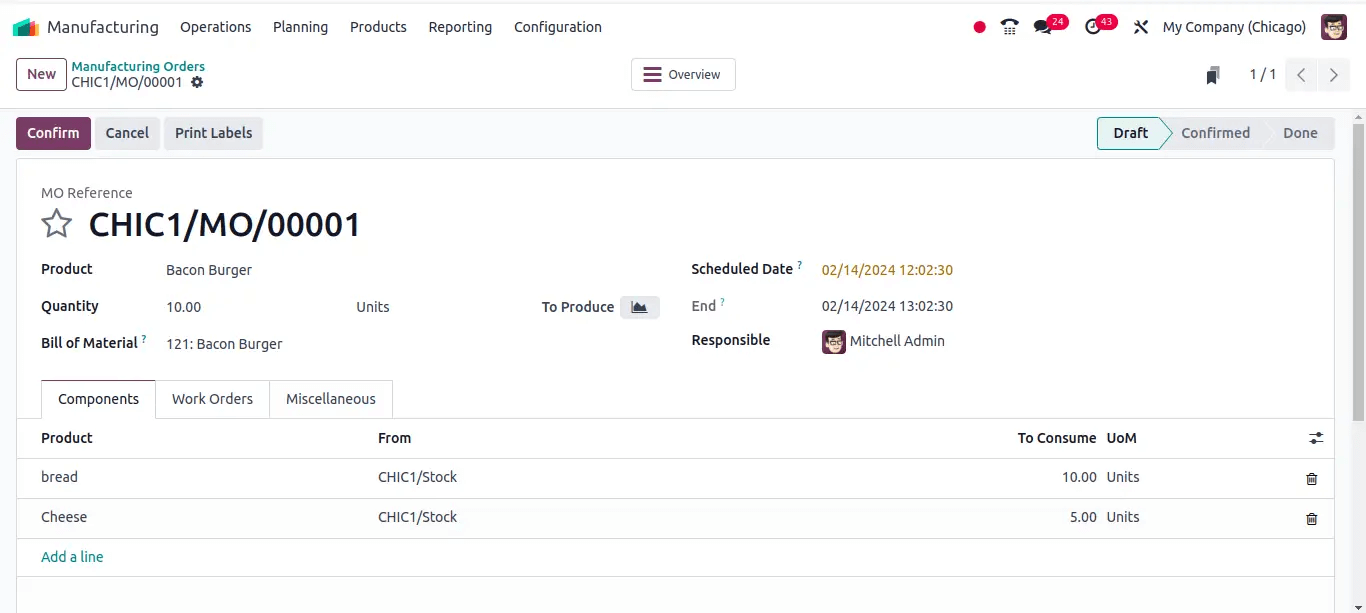

Creation of Manufacturing Order

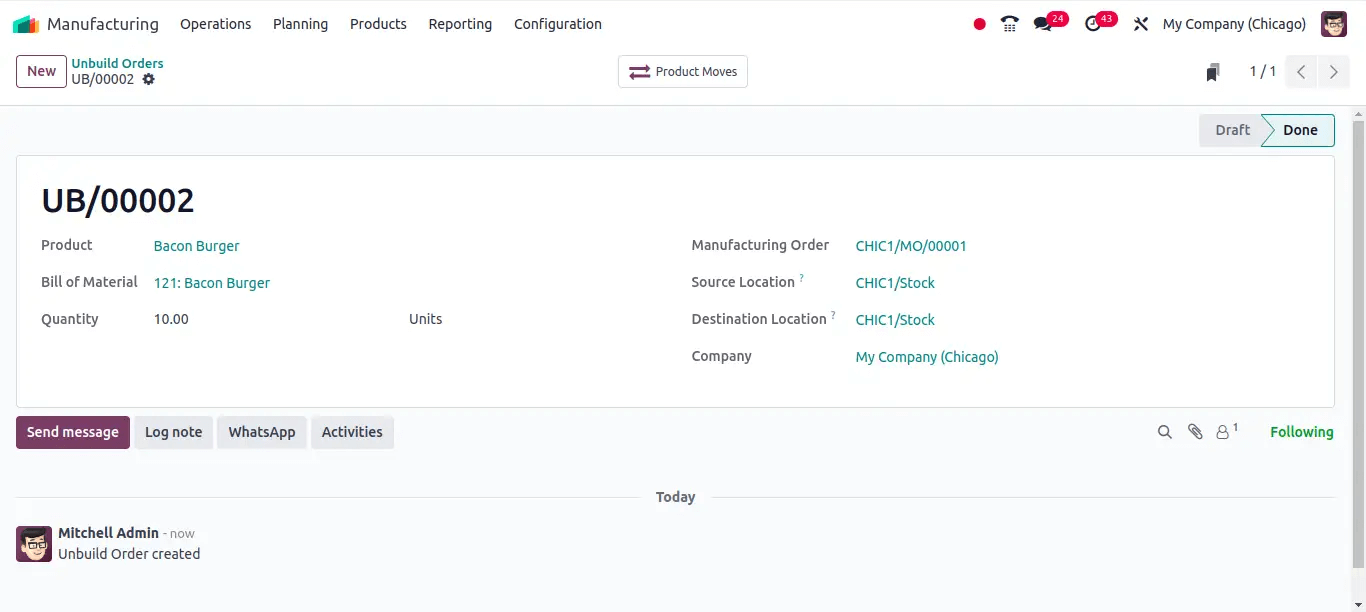

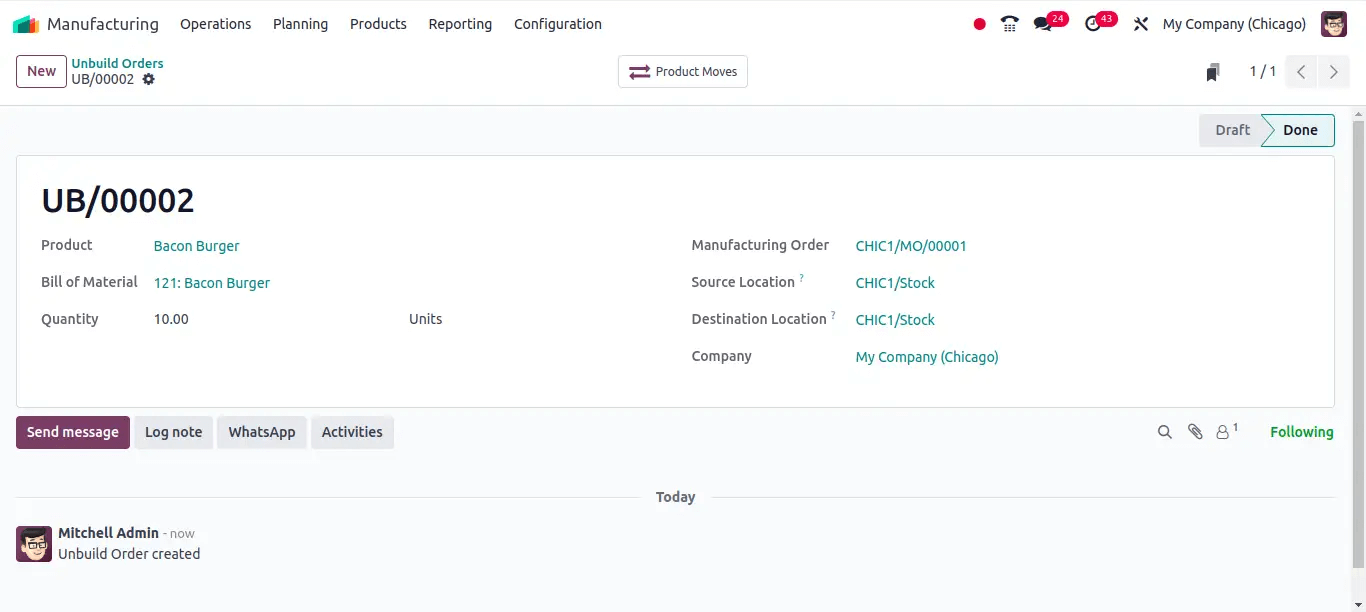

Unbuild Orders

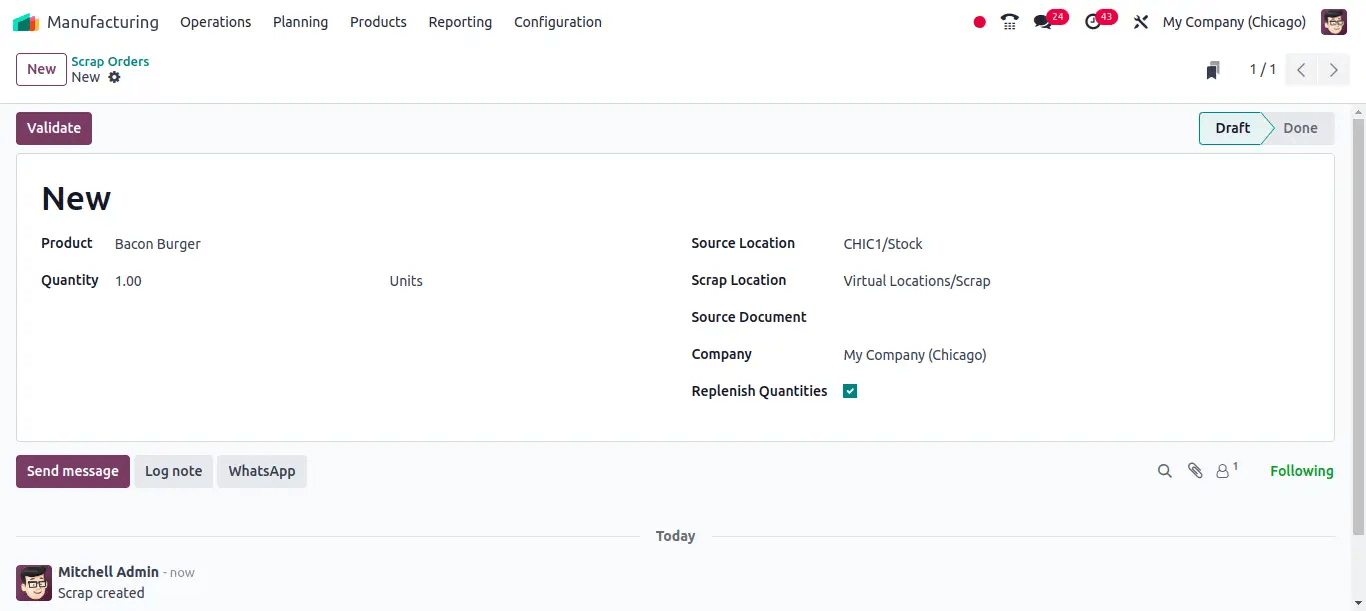

Scrap Orders

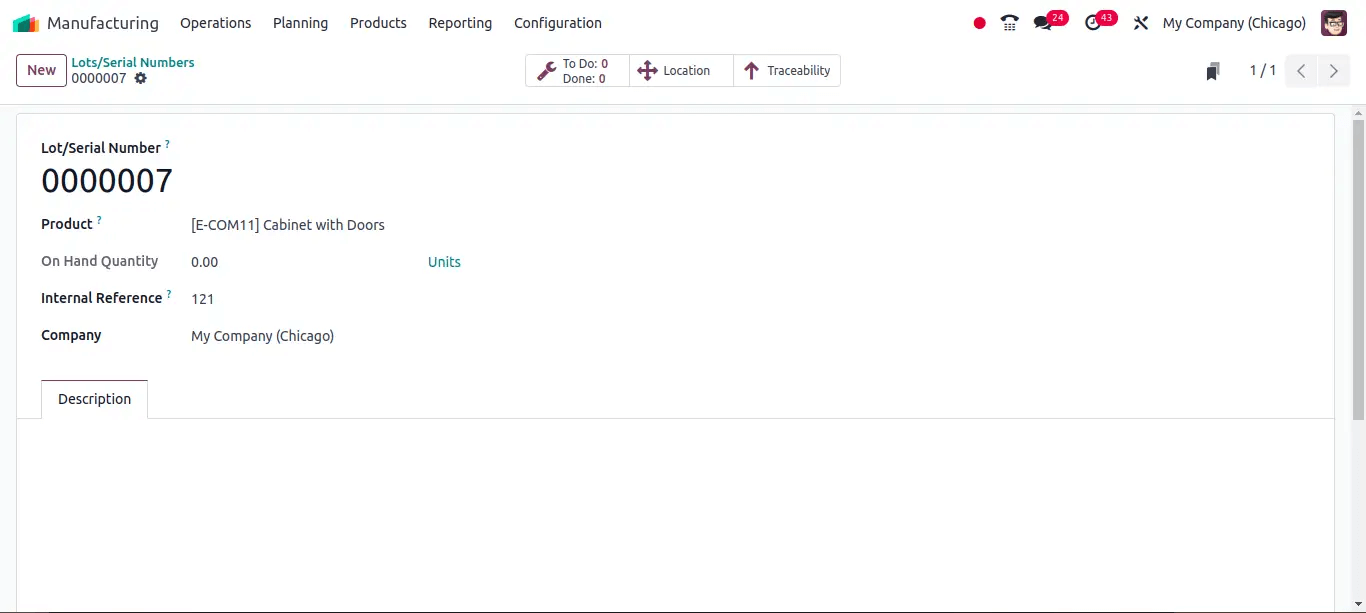

Lot/Serial Number

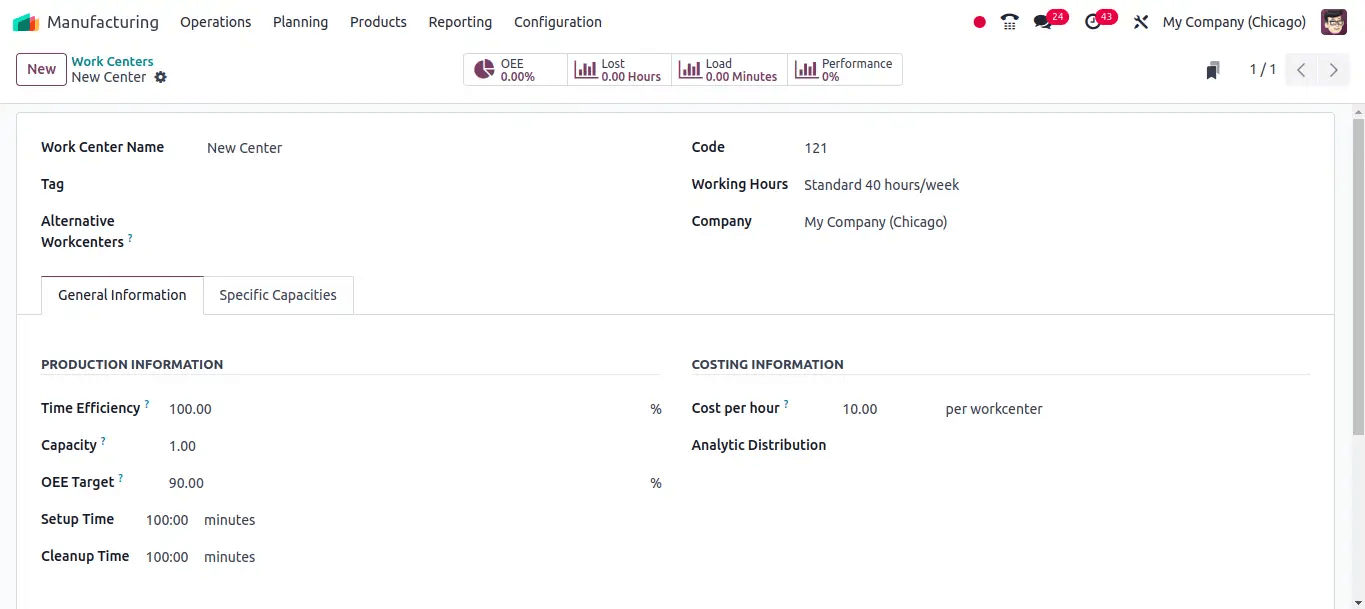

Work center

Operations

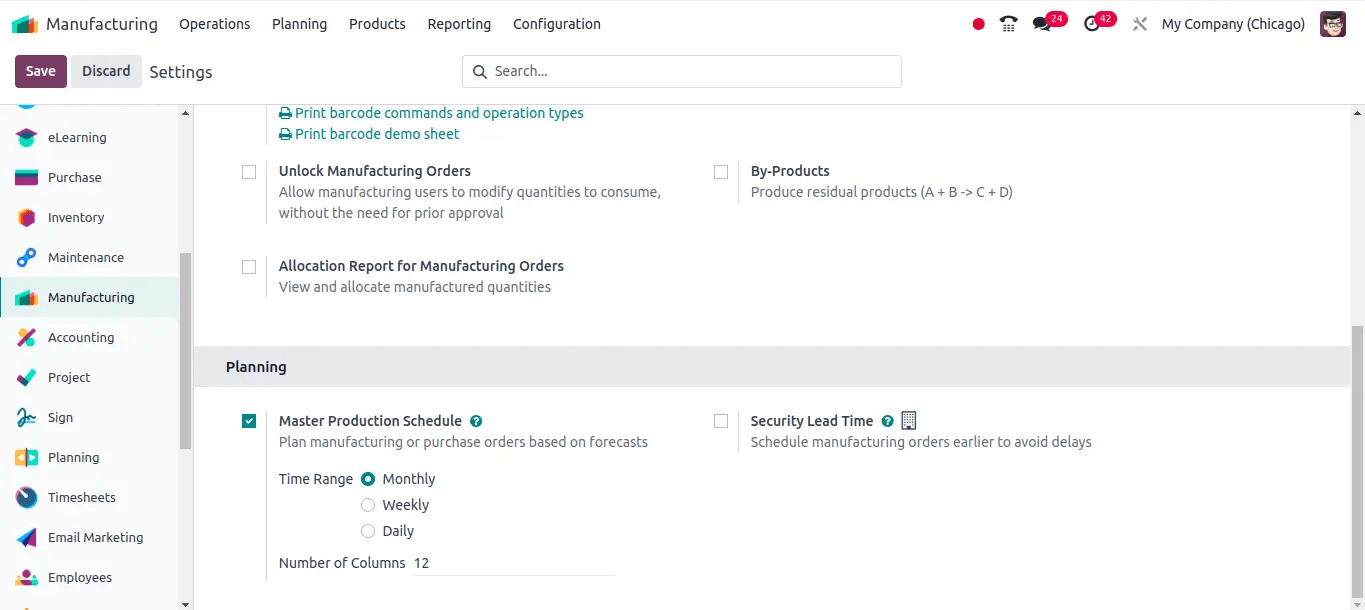

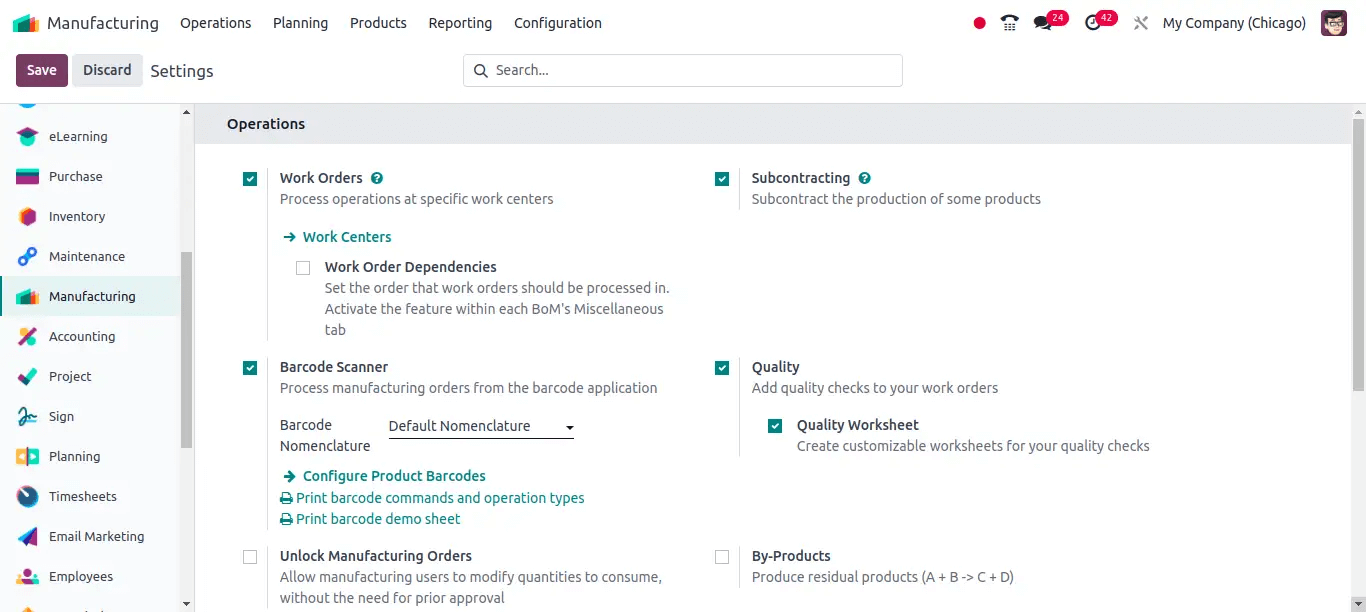

Manufacturing Settings Configuration

Macrofix

Get Started Today

Are you ready to transform your manufacturing operations with Odoo Manufacturing Management Software? Call us at +91 8074391362 or Watch a free demo today.